Research Commercialization Engineering

We work alongside research institutions and commercial businesses to provide mechanical design and physics-based analysis services to support project scaling, process optimization, machine development, and cutting-edge device innovation.

Regulatory & Grant Compliance

Experience in addressing and supporting regulatory, grant, and investment requirements that may apply to the research innovation.

Technical Expertise

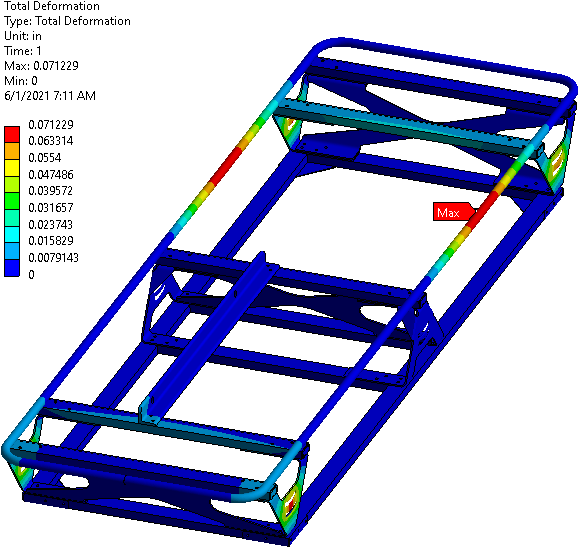

Extensive technical expertise in the thermal management field, particularly in designing components for efficient packaging and cooling of electronics for energy efficiency and reliability.

Engineering Design & Prototyping

Refine and optimize component, assembly, and system design and analysis. Then conduct testing and validation through prototype fabrication and testing.

Bridge the Gap Between Research and Market

Leverage our expertise in mechanical design, physics-based analysis, and manufacturing processes to commercialize your research. We work to ensure products, devices, and machines meet specifications before anything gets built with our process of integrated design & analysis.

You retain full ownership of all Intellectual Property (IP). As your engineering partner and subcontractor, we adhere to a transparent billing approach based on standard time and materials rates.

We have direct experience designing the following industries.

- Hydrogen Energy & Storage

- Carbon Capture

- Nuclear Energy

- Battery Systems

- Electronics Packaging & Cooling

- Directed Energy Weapons

- Networking Devices

- Radar

- Medical Devices

Trusted by Credible Organizations

Johnston Engineering President, Andy Johnston, serves on the board of Evergreen Bioscience Innovation Cluster. We work closely within the cluster to provide our clients with more than just engineering expertise - we also provide the necessary information and connections to professionals in regulatory compliance and IP protection that are needed to successfully bring their products to market.

We have extensive experience in developing medical and dental devices, from consumer use to surgical applications. In fact, as of recently, we've even had experience from your side, as Andy brings his own product, the HAA Backsaver, to market after obtaining FDA approval.

Mechanical Design

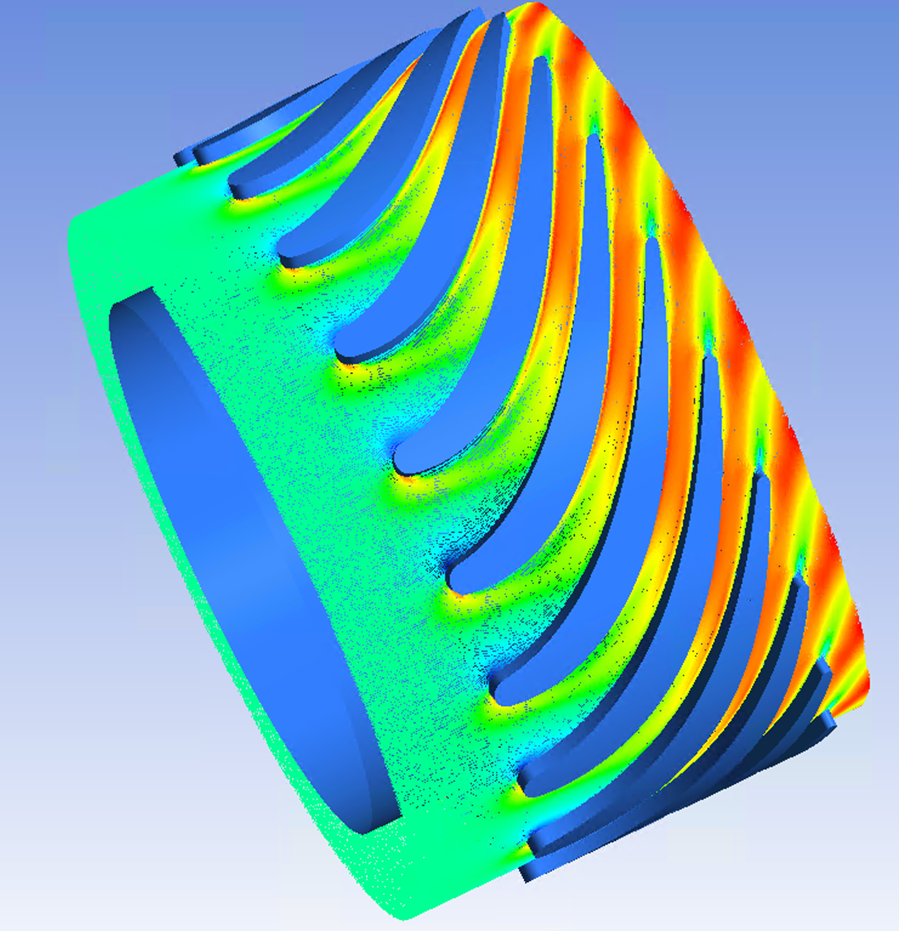

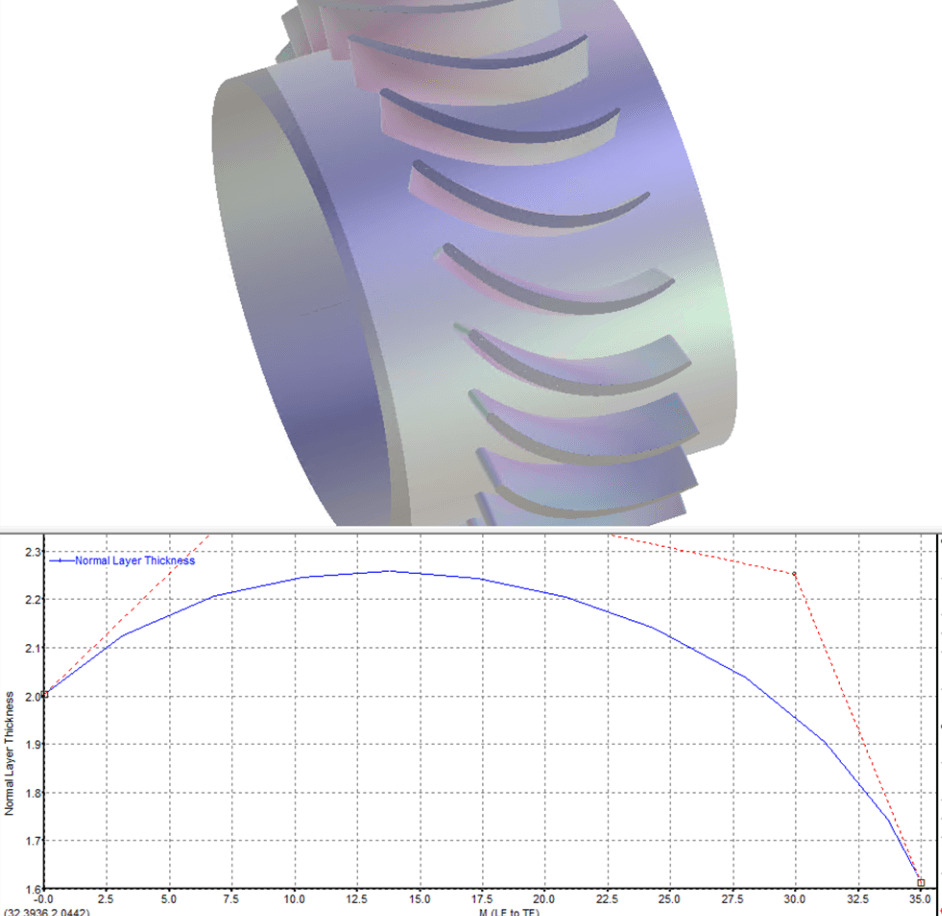

Design using SolidWorks 3D CAD modeling and test using ANSYS engineering software. Models are designed for manufacturing.

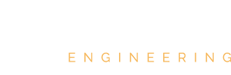

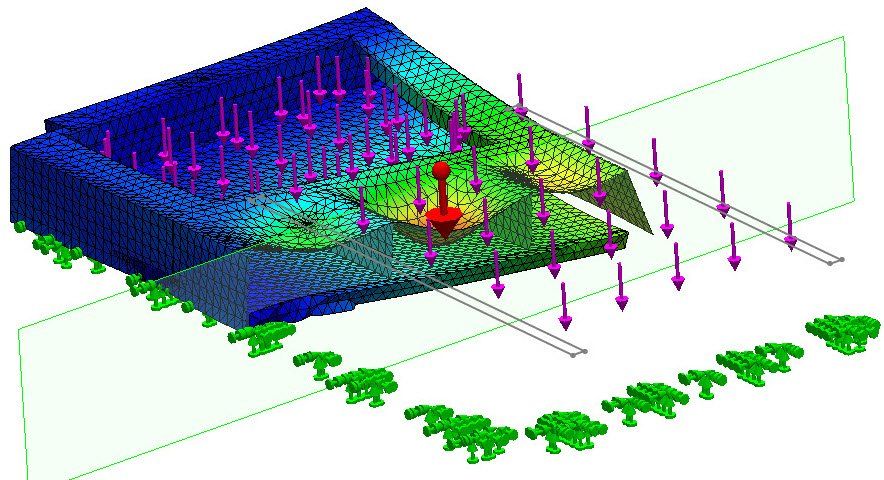

Thermal FEA using ANSYS to simulate how materials respond to heat, energy and temperature loads to ensure optimal thermal performance.

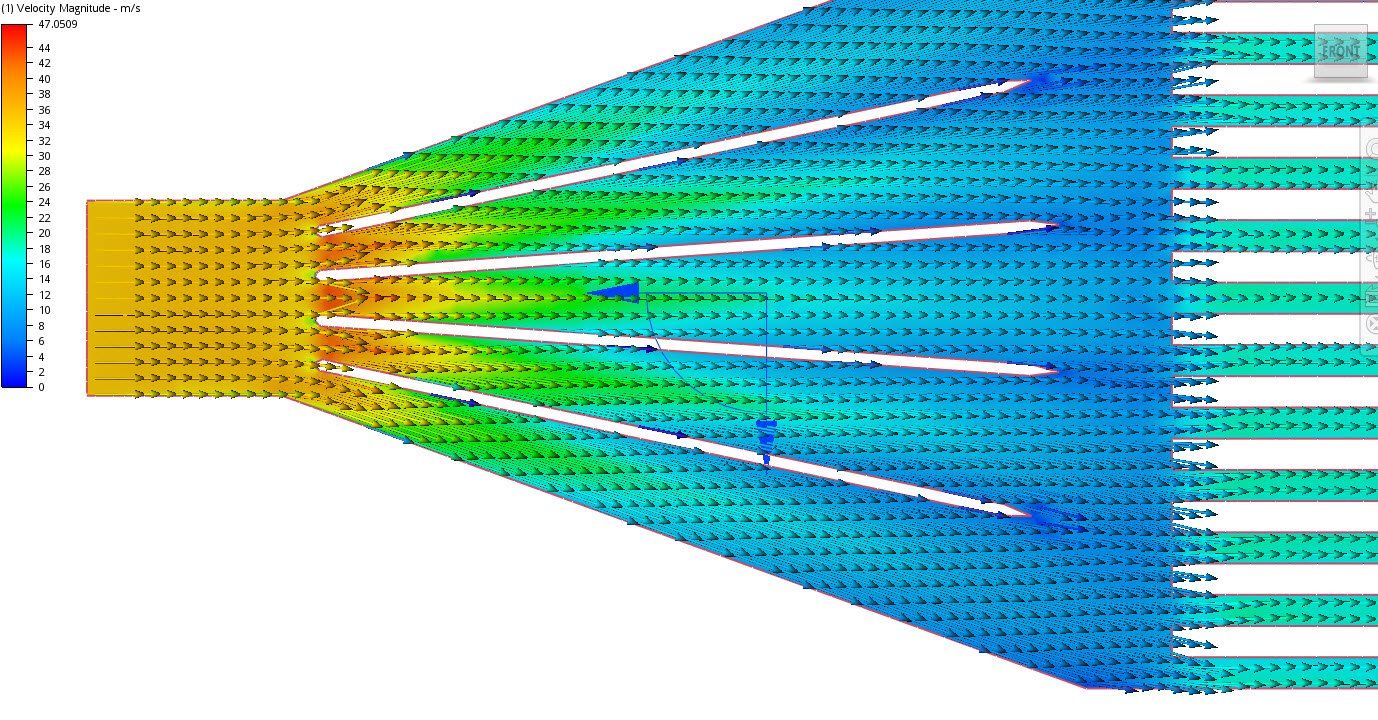

Calculate velocity distribution, density, temperature, heat transfer, pressure drop, flow rates, and fluid distribution.

Move Forward With Confidence

We want to help scale up your research and take your project to the next level.