Design with Composite Materials

Understanding the mechanics and limits of composite materials is essential for designing and engineering products that meet performance, durability, and safety requirements.

Let us design and engineer products that exceed your expectations!

Our Experience with Challenging Environments Using Composite Materials

- Design of structures in high voltage or high current environments

- Design of structures in high magnetism environments

- Design of structures in highly corrosive environments

Our Experience with Challenging Environments Using Composite Materials

- Support plates

- Custom inductor design

- Custom capacitor structural design

- Custom transformer bobbin design

- High energy wire termination blocks

- Structural support

- Electrical component mounting and isolation plates

- Electrolyzer cell-to-cell insulation plates

- Joining of composite materials with non-conductive fasteners

- Custom fiberglass wound components and enclosures

- Highpot testing (high potential) of composite systems

- Structural thermal insulation in demanding environments

We have experience designing custom machined, routed, and turned composite material and can design and build your component or subsystem. We integrate composites with electrical components and conductors (like bus bars, wiring, fusing, safety systems, etc.) and we can deliver a fully built and tested system on your timeline. We have designed many systems using G10, G12, GPO3, FR4, fiber glass structural members, and fiber glass reinforced fasteners. Composites fabrication is inherently challenging and typically has long lead times, but we have experience and a supply chain to accomplish composite design and fabrication work quickly.

Composite Analysis Capabilities

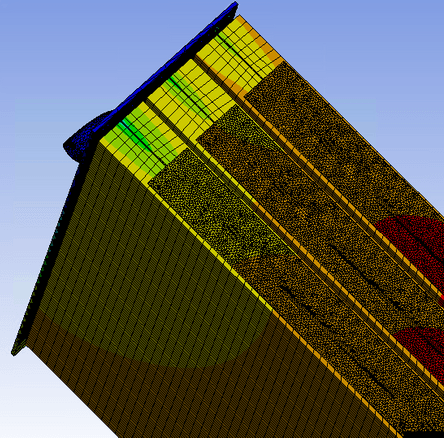

- Structural analysis of composite components and systems using Structural FEA

- Structural members

- Support plates

- Device and component isolation plates

- Components experiencing transient forces from alternating high magnetic loads

- Thermal analysis of composite systems using Thermal FEA

- Steady-state heat transfer through isolation components and structural components

- Transient analysis of high repetition rate thermal loads through isolation components and structural components

Use of Composite Materials in Engineered Systems

In mechanical engineering, composites refer to materials that are made up of two or more constituent materials with different physical or chemical properties. These constituent materials are typically combined to create a material with superior mechanical properties compared to the individual materials on their own. An example of commonly encountered composite material is glass fibers and epoxy. Composite materials have unique mechanical and physical properties that differ from traditional materials like metals and plastics, making them ideal for certain applications where high-stress, durability, electrical conductivity, and resistance to heat, moisture, and chemicals are needed. Composite materials generally have an increase in cost over typically encounter materials and should only be used when they are required. We use composite materials in electrical systems that need strength and rigidity while interacting with hazardous voltage, current, or corrosive materials.

Engineering With High Stress and Heat

Our team of expert mechanical engineers and designers has worked on a diverse range of projects, from aerospace to nuclear energy, utilizing composite materials to create lightweight, durable, heat-resistant, and high-performance products.

We bring a deep understanding of materials science, engineering analysis, and manufacturing techniques to every project, enabling us to deliver products that are not only high-performance but also reliable, safe, and cost-effective.

Our team has extensive experience applying composite materials to a range of industries, including aerospace, medical, energy and battery storage and pulsed power networks.

Move Forward With Confidence

We validate composite materials to ensure that required specifications and standards for the intended application are met early in the design process.

Material Selection and Testing

Choose the right composite materials and conduct material testing to ensure materials meet the necessary specifications.

Structural Analysis and Design

Determine the load-bearing capabilities and design structures that are optimized for strength and durability.

Finite Element Analysis (FEA)

Simulate the performance of composite materials and structures under various heat and stress load conditions.

Designing With Composite Materials?

We want to know your needs exactly so we can provide the perfect solution.